Category: Safeguarding Accessories

Showing 49–72 of 82 results

-

Maximum Load Safety Block Label (KST330)

$20.57The Maximum Load Safety Block Safety Label (KST330) is designed to be a visual warning of a maximum load to alert persons in the work place.

-

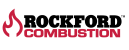

Milling Machine Belt Cover (KYL021J)

$282.44This unique patented milling machine belt cover is made of durable cast aluminum. The hinged covers are sold in pairs for the right and left sides and are permanently attached to the machine. Spindle speed changes are done quickly and efficiently by simply pulling down the belt cover. OSHA requires under 29 CFR 1910.219 that…

-

Milling Machine Draw Bar Cover (DBC001)

$180.03This Draw Bar Cover (part #DBC001) protects vertical mill workers from rotating shafts below 7 feet off the ground. It guards the turning draw bar with a non-rotating, smooth, welded-steel enclosure, secured firmly to the mill with a powerful ring magnet and safety anchor chain. Simple to install, the draw bar cover prevents clothing, hair…

-

Danger Signs for Moving Saw Blades (KSC058-KSC058S-KSC058F)

$35.70These visual safety tools are to raise awareness of the danger of moving parts on machinery. Signs are available in English, Spanish, and French. Ex. “You are exposed to moving machine parts that will result in loss of fingers if placed in the machine.”

-

Non-Locking Safety Switches—Metal Housing

$689.02 – $797.64These tamper-resistant safety switches can be used to interlock hinged, sliding, or lift-off guards. Closure of the guard or latch causes the actuator to enter the switch and release the dual anti-tamper locking cams. The actuator allows the main center cam to rotate and make the switch contacts. When opening the guard or latch, the…

-

Non-Adjustable Floor Stand for Control Bar or Palm Button Assembly (KCL000)

$1,495.97This 37″ nonadjustable heavy-duty floor stand includes a top plate and a 4″ x 4″ column. The base has four holes for permanent attachment to the floor; bolts are not furnished.

-

Notice For Metal-Forming Machinery (KSC033)

$35.70This safety tool is used to raise awareness of the dangers of metal-forming machinery in the workplace.

-

Operator Safety Signs (Cutting/Turning KSC048-KSC048S-KSC048F and Forming/Fabricating KSC000-KSC000S)

$35.70Cutting/Turning and Forming/Fabricating Specific Operator Safety Signs are available in English, Spanish and French. Ex. “Never place your hands in this machine.”

-

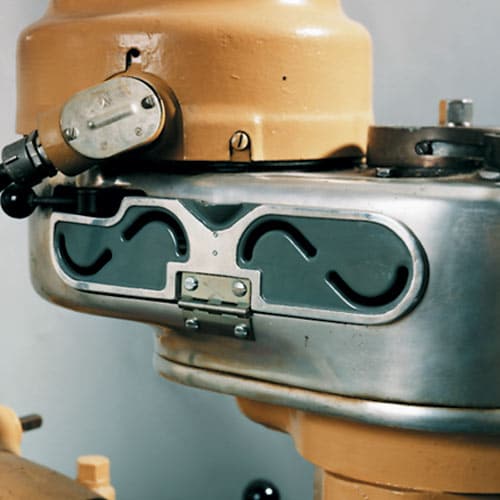

Guard Opening Requirements Sign OSHA (KSC012)

$35.70This guard-opening sign is based on Table O-10 of OSHA 29 CFR 1910.217 for mechanical power presses, which shows the distances that guards shall be positioned from the point of operation based on opening size. This sign can be used by engineering, maintenance, etc., for reference when designing or fabricating guards. This 10″ x 12″…

-

Palm Button Assemblies – Black Palm Button (CTC726)

$644.01This standard heavy-duty, single plunger run palm button provides one normally open and one normally closed contact arrangement. This 2 1/4″ button is mushroom-shaped. The palm button face plate has a solid neoprene gasket which provides an oil-tight seal upon installation. When applying two-hand control as a safeguard to any machine, fixture, device, etc., the…

-

Palm Button Mounting Boxes

$72.94 – $142.77Part No. CTK-004 Single-hub mounting box is used when wires terminate at this box. Part No. CTK-003 Double-hub mounting boxes are used when wires are required to go through the box and on to another mounting box. Part No. CTK-038 Deep single-hub mounting box is used when wires terminate at this box. Part No. CTK-039…

-

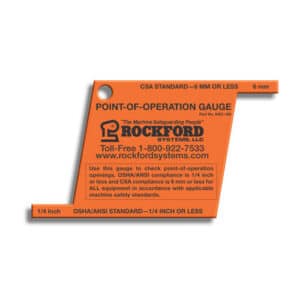

Point-Of-Operation Gauge (KSC100)

$40.35The point-of-operation gauge is designed to be used as a quick reference tool to check for what OSHA regulations and ANSI standards refer to as safe-opening. It is a valuable tool to use during the design, installation, and inspection of guards to make sure the openings do not exceed 1/4″ (6 mm) for OSHA/ANSI and…

-

Portable Welding Screen and Grinding Station Screen (PTS01200)

$2,866.23This portable welding screen offers protection for personnel who are in the area of welding and grinding work zones. The .4 mm-thick, semi-transparent PVC screen protects personnel from metal chips and sparks produced during the welding and/or grinding process. The red PVC screen pulls out easily from the mobile stand and attaches to a center…

-

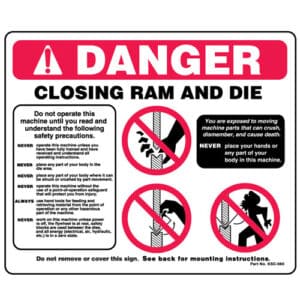

Danger Signs for Press Brakes (KSC060-KSC060S)

$35.70Press Brake Danger, Visual Safety Signs (KSC060-KSC060S) are designed for visual danger awareness. Sign are available in English and Spanish.

-

Right Angle Rigid In-Line Actuator (CMC547A)

$80.70In-line safety actuators must NEVER be used to bypass or otherwise defeat the protective functions of the safety switch.

-

Warning Label for Rotating Gears and Pulley (KST181)

$19.78Rotating Gears and Pulley Danger Labels (KST181) are designed to raise awareness of the dangers with rotating gears and pulleys. Ex. “You are exposed to moving machine parts that can crush, dismember, and cause death.”

-

Safety Bumper

$670.40 – $1,466.47This safety bumper system is designed to protect someone or something from hazardous machine conditions. A safety bumper and a safety interface control provides a Category 3 safety system. The bumper is an industrial grade, pressure-sensitive safety device with a built-in sensor, and is supplied with 4-lead wiring. When a person or object comes in…

-

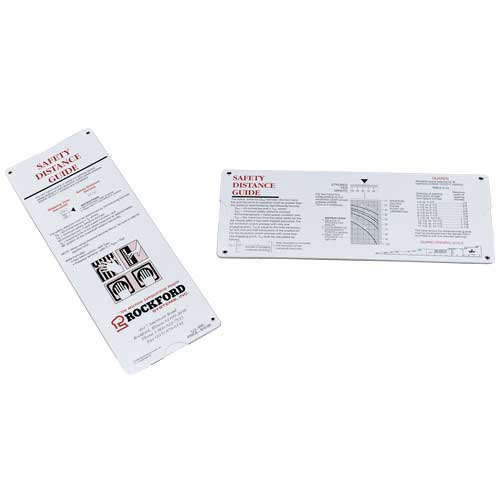

Safety Distance Guide Slide Chart (LLL050)

$27.16This slide chart calculates the safety distance for mounting two-hand trip, two-hand control, and presence-sensing devices on machinery.

-

Self-Ejecting Lathe Chuck Wrenches

$394.16 – $504.34Lathe chuck wrenches help prevent one of the most common accidents on lathes: when a chuck wrench (or key) is thrown from the chuck. This happens when someone forgets to remove the chuck wrench from the chuck before the machine is turned on. A self-ejecting, spring-loaded chuck wrench can be used on lathes or other…

-

-

Slim Line Non-Locking Safety Switches

$336.74 – $446.92Tamper-resistant safety switches can be used to interlock hinged, sliding, or lift-off guards. Closure of the guard or latch causes the actuator to enter the switch and release the dual anti-tamper locking cams. The actuator allows the main center cam to rotate and make the switch contacts. When opening the guard or latch, the actuator…

-

Solenoid Locking Safety Interlock Switches

$1,359.41 – $1,657.36Kit includes switch, actuator, and conduit adapter. Locking switches are designed to prevent accidental or deliberate access while the machine is in motion. The mechanical locking feature is ideal for machines that have to finish a sequence, a program, or coast to a stop before the interlocked guard can be opened. The switches allow the…

-

Spring-Loaded, Self-Ejecting, Safety Turnover Bars

$336.74 – $533.84Spring-loaded turnover bars are most frequently used with mechanical power presses. Turnover bars can also be used on four-slides or any other machine where the bar might be sent into the air if it is inadvertently left in the bar ring hole and the machine is turned on. Each spring-loaded turnover bar is self-ejecting so…

-

Spring-Loaded/Self-Ejecting Drill Press Chuck Keys

$54.30 – $276.22Use the chart below to select your drill press chuck key. These drill press chuck keys are spring-loaded and self-eject so they are not inadvertently left in the drill’s chuck. Drill Press Chuck Keys – Pilot Size Selection Chart

Contact Customer Service Reach a Live Person @

Open Monday – Friday

8:00am – 5:00pm CST

Order Online Today

Let Us Help…

Our Mission

To reduce risk and prevent workplace

injuries by becoming our customer’s trusted

advisor and source for machine safeguarding

training, assessment services, and provider

of turnkey engineered safeguarding solutions.

Location

5795 Logistics Parkway

Rockford Illinois 61109

Phone

1-800-922-7533

Useful Links

Hours of Operation

Copyright 2024. All Rights Reserved By Rockford Systems LLC