Full Revolution Clutch Press Controls (FPA, FPG, FBH)

Product Description

The electro-pneumatic trip-control system is designed for use on fullrevolution- clutch mechanical power presses. It is designed and built to comply with OSHA 29 CFR 1910.217 and ANSI B11.1 and B11.19. This control updates full-revolution-clutch presses that do not presently have single-stroke capability. It can also be a replacement for existing trip-control systems.

This control is an economic, full-featured microprocessor-based press trip control. The system uses a microprocessor to cross-check and monitor the control relays. In the event of a control malfunction, further operation is prevented. See page 111 for details on control reliability.

The multi-tap transformer has a 115-, 208-, 230-, 460-, and 575-V primary, 115V secondary, and 100-VA rating. This control must be wired in to a motor starter that has a 115V operating coil. This provides primary power to the clutch control and to the control box for the twohand motor jog mode of operation.

The standard control box is housed in a 16” x 10” x 6” NEMA 12 enclosure. The ground indicator light and operator controls are located on the front of the enclosure door. The motor controls are usually located in a remote station.

STANDARD MODES OF OPERATION

• Two-hand motor jog

• Two-hand single stroke

• T wo-hand “walk-away” continuous*

• Foot single stroke

• F oot-maintained continuous*

• Automatic single stroke*

• Continuous-on-demand*

*Requires a remote prior-action station.

FEATURES

• Single-stroke capability operation

• Two-hand antirepeat

• Two-hand trip as a point-of-operation safeguard

• Two-hand anti-tie down and concurrent operation

• Controls all types of full-revolution clutches

• Redundant-logic system microprocessor

• Provisions for electrically interlocking safety devices

• Isolated microprocessor logic power supply

• Redundantly monitored solid-state relay/captive-contact

relay output for trip solenoid(s)

• Saddle-clamp circuit board terminal strips

• Supports redundant, self-checking solenoid valves

• Fused SSR (solid-state relay) outputs

• Type A gate interface

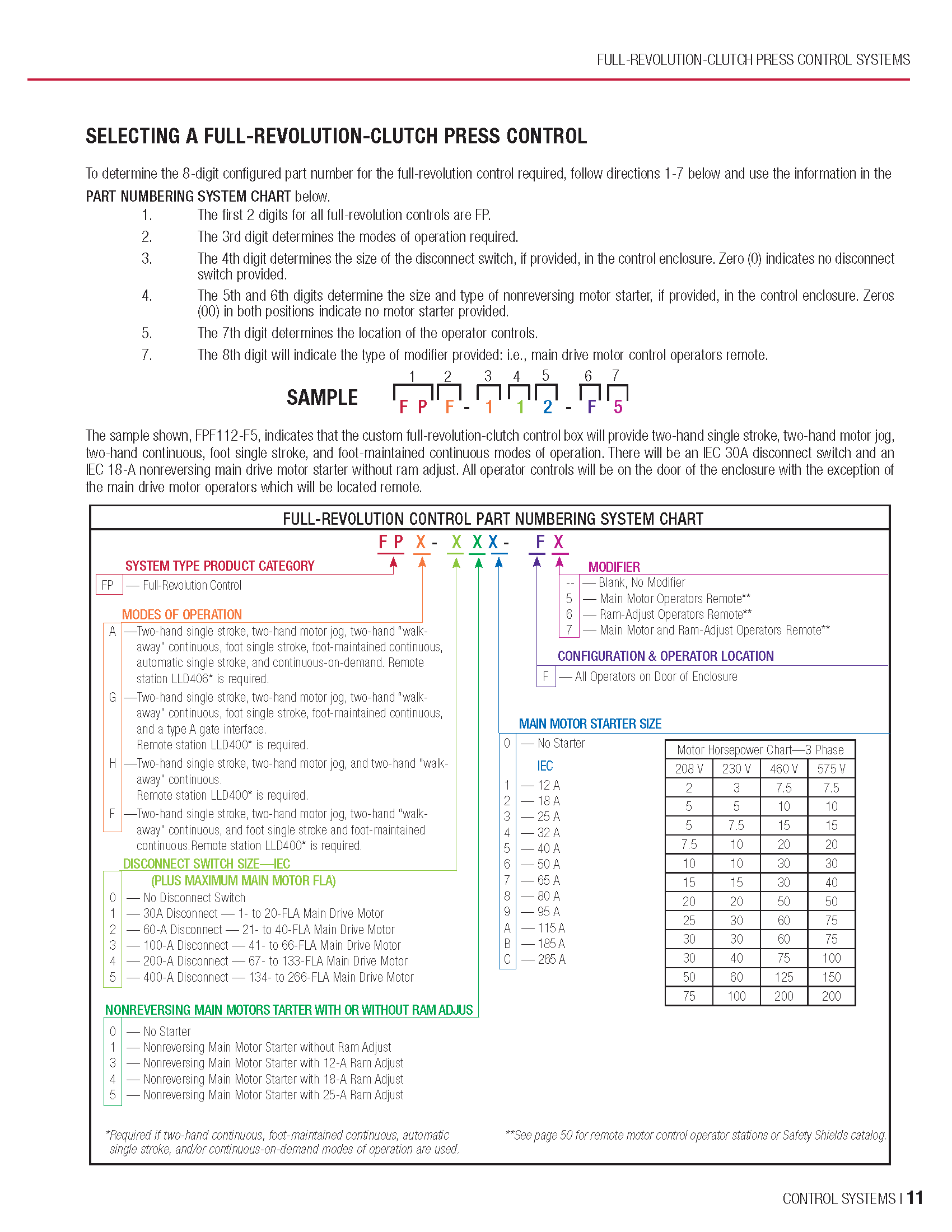

CUSTOM FULL-REVOLUTION CONTROL

Full-revolution-clutch custom control boxes and packages are available to fit your particular press room needs. A custom control box contains the standard control module and components as described on pages 9-10 plus the following:

- main power disconnect switch

- main drive motor starter

- ram-adjust motor starter (if required)

These boxes are furnished with an IEC through-the-door main power fused disconnect switch and an IEC magnetic motor starter (with push buttons). A reversing ram-adjust motor starter with selector and push buttons may also be included. They are prewired and built into a larger NEMA 12 enclosure.

Operator controls are located on the front of the enclosure door. The motor controls can be located in a remote station or on the enclosure door.

NEMA-style disconnect switches and motor starters, and brandname components specified by our customers are also available. To ensure the starter(s) and disconnect are sized properly, please check horsepower for the main drive motor and slide adjust motor (if furnished) on the press, as well as full-load amps, and primary voltage to the press. After obtaining this information, please go to the chart on page 11 to determine the proper custom control box part number. Follow directions 1-7 to determine the correct part number.

Contact Customer Service Reach a Real Person @

Open Monday – Friday

8:00am – 5:00pm CST

Order Online Today

Let Us Help…

Related products

-

-

-

-

Light Curtain Interface for Point of Operation (EZ) Light Curtains

$834.88 – $3,230.91 -

Our Mission

To reduce risk and prevent workplace

injuries by becoming our customer’s trusted

advisor and source for machine safeguarding

training, assessment services, and provider

of turnkey engineered safeguarding solutions.

Location

5795 Logistics Parkway

Rockford Illinois 61109

Phone

1-800-922-7533

Useful Links

Hours of Operation

Copyright 2024. All Rights Reserved By Rockford Systems LLC