Machine Safeguarding

Comprehensive Safeguarding Services for a Safer Workplace

Rockford Systems offers industry-leading machine safeguarding services designed to protect workers, ensure compliance, and prevent downtime. We follow best practices in machine safeguarding, including comprehensive risk assessments, engineered control solutions, proper training, and regular safety audits. From identifying hazards to implementing custom solutions and providing ongoing support, we help businesses reduce risk, maintain safety standards, and foster a culture of workplace safety.

Expert Safeguarding Services Tailored to Your Needs

Rockford Systems offers a full range of machine safeguarding services to help businesses protect workers, ensure compliance, and improve efficiency. From risk assessments to custom safeguarding solutions, our experts provide the support needed to keep your machinery safe and OSHA/ANSI compliant. Explore our services to find the right solutions for your workplace safety needs.

Take the Next Step Toward Workplace Safety

Our experts are ready to assess your safeguarding needs and provide tailored solutions. Contact us today to discuss your safety challenges and find the right services for your business.

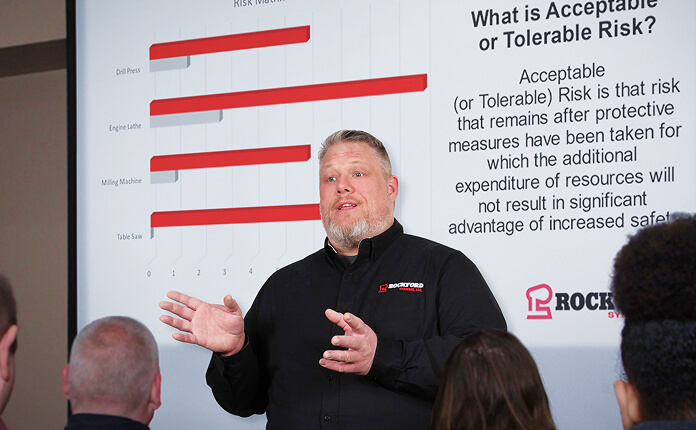

Rockford Systems offers expert-led training programs, workshops, and seminars to educate teams on machine safeguarding best practices, OSHA and ANSI compliance, and risk reduction strategies. Our tailored training empowers employees to create a safer, more compliant workplace.

Rockford Systems offers a vast selection of safeguarding products, including shields, barriers, presence-sensing devices, and control systems. Designed to meet OSHA and ANSI standards, our products help businesses enhance workplace safety, reduce risks, and ensure compliance.

Rockford Systems follows a proven, step-by-step process to ensure effective machine safeguarding. From initial risk assessments to custom-engineered solutions, installation, and compliance validation, our expert-driven approach ensures safety, efficiency, and regulatory compliance at every stage.

How Our Safeguarding Services Make a Difference

See how Rockford Systems has helped businesses like yours enhance safety, improve compliance, and reduce risk through expert safeguarding services.

Benefits of Machine SafeguardingProtect Workers, Ensure Compliance, and Enhance Efficiency

Effective machine safeguarding protects employees, ensures compliance, and boosts efficiency. By reducing workplace injuries, meeting OSHA and ANSI standards, and optimizing productivity, Rockford Systems’ solutions create safer, more reliable workplaces across industries.

Comprehensive Safety Solutions for Any Industry

Rockford Systems provides machine safeguarding solutions tailored to the unique risks and regulations of various industries. From manufacturing to food processing, our expertise ensures compliance and worker protection in high-risk environments.

Manufacturing

Protecting workers from hazardous machinery in metalworking, welding, and fabrication operations

Automotive & Aerospace

Safeguarding production lines, stamping presses, and robotic systems to meet industry safety standards.

Food & Beverage Processing

Reducing risks in food manufacturing with safety solutions for slicers, conveyors, and automated packaging.

Energy & Utilities

Ensuring compliance and safety in power plants, refineries, and utility operations.

Oil & Gas

Protecting workers from high-risk equipment in drilling, refining, and processing environments.

Pharmaceutical

Enhancing workplace safety in precision manufacturing, medical device production, and lab environments.

Logistics & Warehousing

Protecting workers around conveyors, AS/RS systems, pallet wrapping machines, and packaging equipment—such as box erectors and tapers—in fast-paced distribution environments.

Government & Defense

Providing safeguarding solutions for defense contractors, government facilities, and military applications.

Find Safety Solutions for Your Industry

Contact us to learn how Rockford Systems can help your organization reduce risk and improve employee safety.

Open Monday – Friday, 8:00am – 5:00pm CST. Same day email support responses.