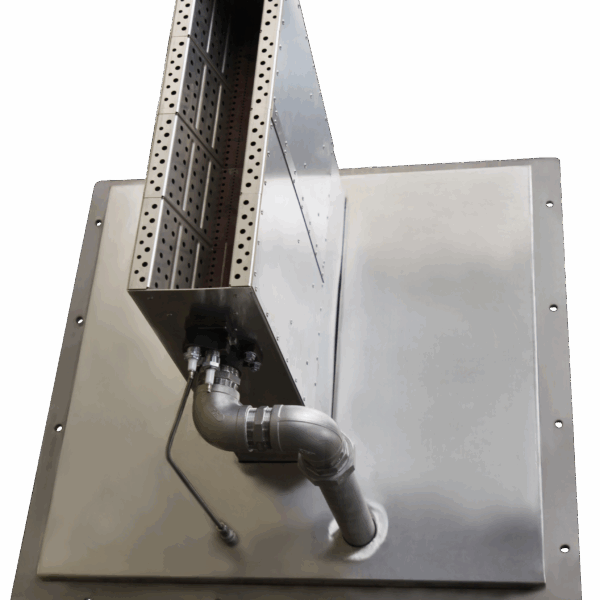

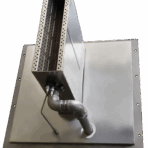

ANM 75 Series – Duct Burner

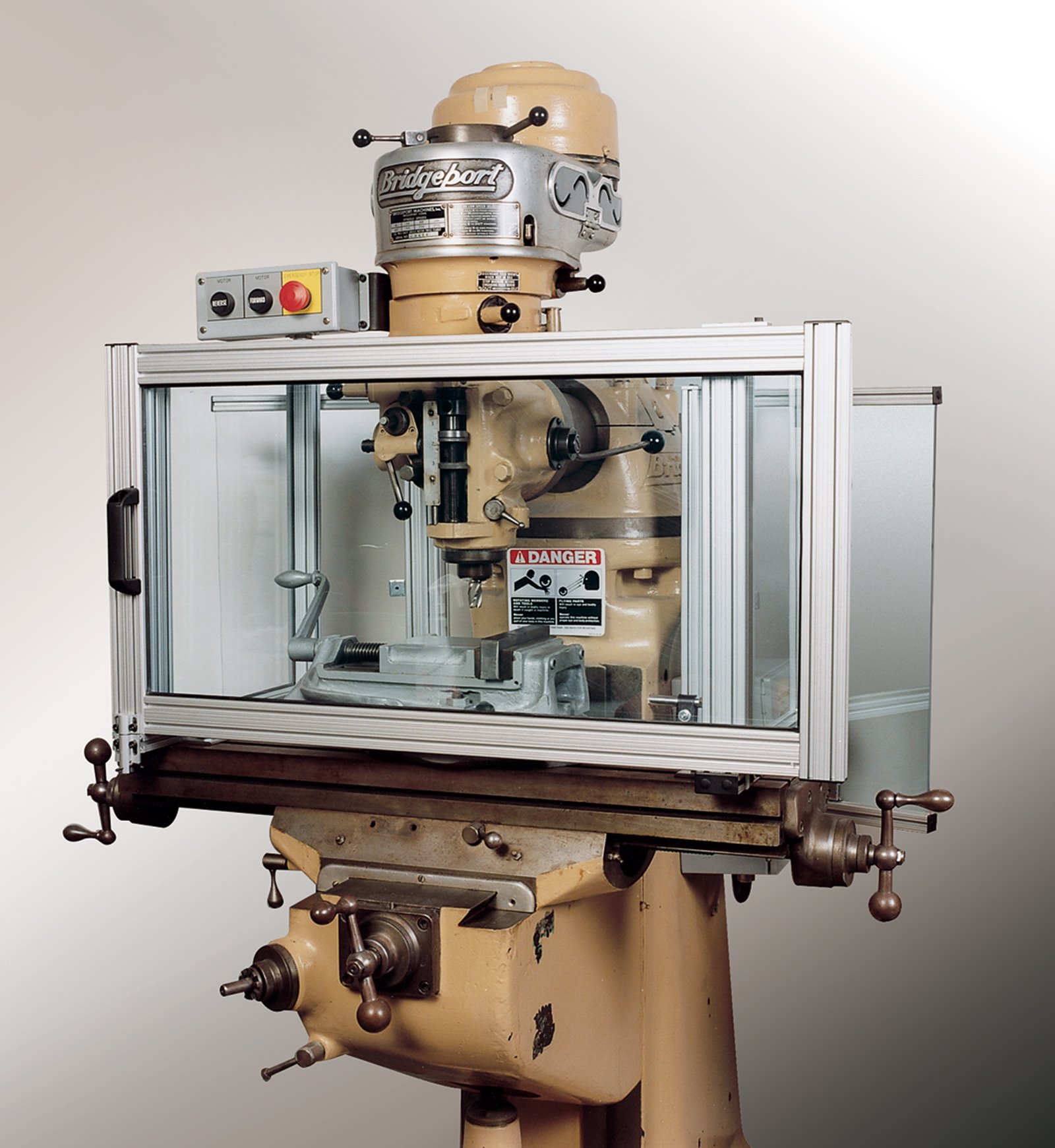

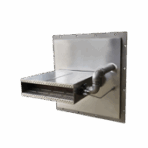

This series burner is duct heating burner, large amount of circulating air passes through the burner and be heated, enters into the drying room. Both packaged blower and remote blower are available.

Product Description

ANM75 series burners are line-type burners ideal for generating large volumes of clean, hot air. This series of burners was designed with modular concept; burner shape depended on local duct dimension, it can be designed best fit the process duct for even mixing. Applications include ovens, dryers, fume incinerators, and similar industrial equipment especially used in the food, gypsum industry.

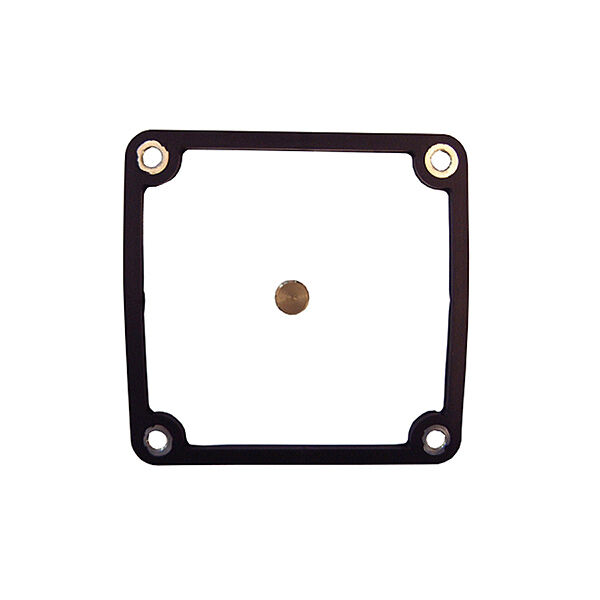

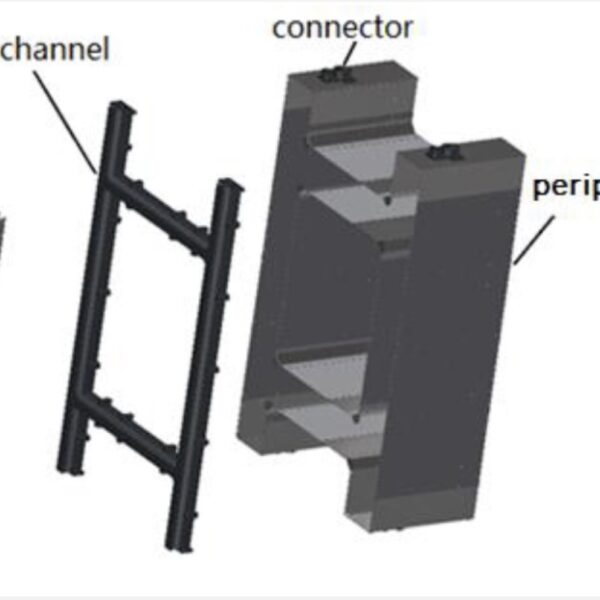

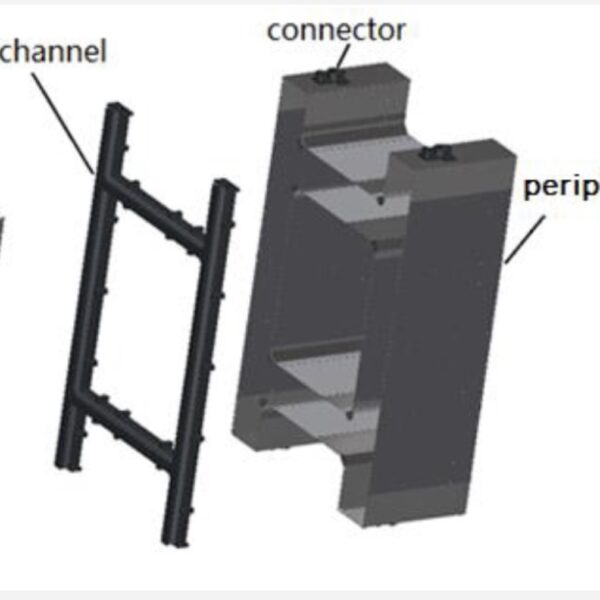

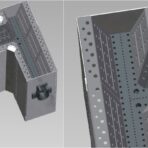

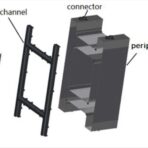

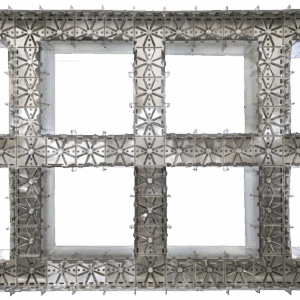

Burner adopts a modular structure, each module size is 300×176.5 or 150 x 176.5 mm. According to the customer duct size, the burner could be designed as linear type, square, or cross in square to ensure a uniform temperature in the process air duct section.

Contact Customer Service

Reach a Real Person @: 1-800-922-7533

Open Monday – Friday, 8:00am – 5:00pm CST

Same Day Support Response

-

- Fuel type: natural gas

- Combustion air: fresh air

- Capacity range: modular design, customized

- Maximum temperature: 450

- Turndown ratio: 40:1

- Low NOx emission

ANM 75 Series is a patented product of Anderson Thermal Solutions

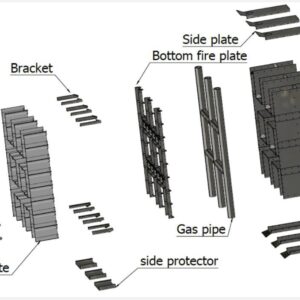

- This type of burner is duct burner which is ideal for generating large amount of clean circulating hot air

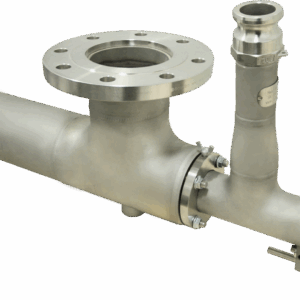

- End part of the burner supplies fuel to the center, and the side plate distributes the fresh air to the center, special design to make sure the fuel and fresh air mixed efficiently

- Modular type burner, customized capacity output

Burner Parameters

- Temperature upstream burner: -30-400°C

- Maximum temperature downstream burner: 800°C

- Burner ratio: 40:1

- Velocity across the burner: 1.5 ” 3.0 m/s

Typical Applications

- Gypsum board drying

- Food drying

- Feed drying

- Other heating industry

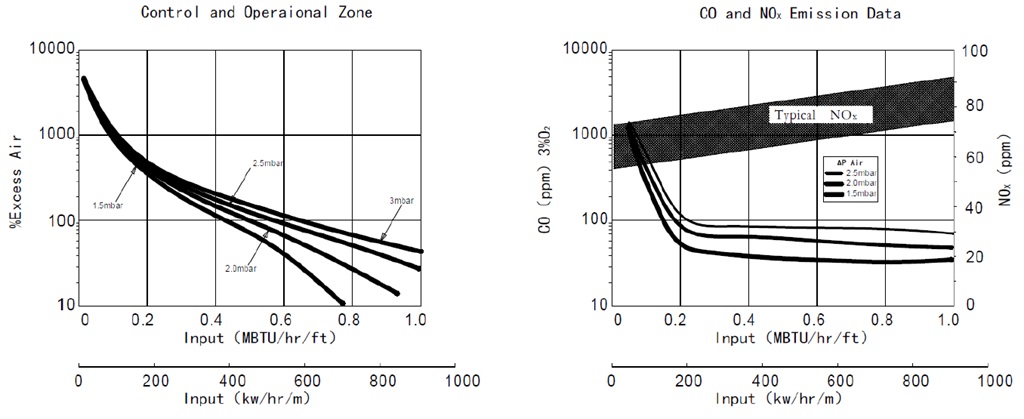

Technical Data

- Maximum output: 960KW/m

- Minimum output: 24KW/m

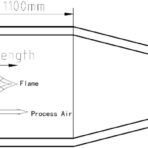

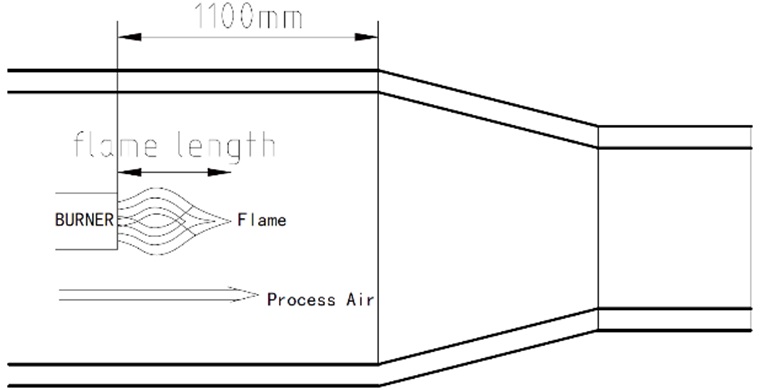

- Flame length: 1100mm

- Downstream temperature: 400

| PARAMETER | SPECIFICATION |

| Maximum input kW | 960 kW /m (air pressure difference 2.5mbar) |

| Minimum input kW | 24 kW / m |

| Typical excess air at maximum | 10% |

| Module length | 300/150mm |

| Gas pressure at nozzle | Natural gas: 22mbar |

| Air pressure drop over the module | 1.5 to 3.0 mbar |

| Max flame length | 1000mm |

| Module dimensions | 300/150X176.5 mm |

| Flame length from stabilization plate | 1500 mm |

| Ignition system | Pilot |

| Flame supervision | UV scanner or flame rod |

| Control method | Mechanically or Electronically Linked Valves |

Notes:

- Above data is based on net heat value (HHV).

- Normal condition: 1 atmosphere, 0°C

- Actual data varies by each application condition.

- Anderson Thermal Solutions (Suzhou) Co., Ltd reverse rights for modification without notice.

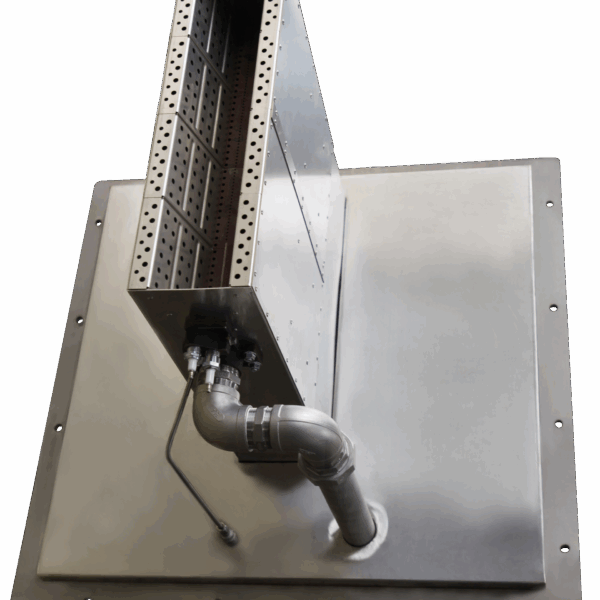

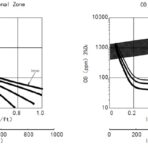

Fig ANM75 Series Burner Installation Layout

- Data came from Anderson Laboratory tests with a process air 11 times combustion air and a burner of 12 modules.

- Anderson retained the authority to change the experimental data after further tests.

| SKU | Weight | Dimensions |

|---|---|---|

| ANM 75 Series | N/A | N/A |

Rockford Products