Training at Rockford Systems

For over 50 years, we have been educating organizations, on workplace safety solutions, risk aversion, and standards/regulations. We offer numerous types of training that can be customized to fit your safety needs. Whether you are a safety manager, engineer, or anyone responsible for machine safety, lockout/tagout, or combustion safety these training sessions can provide you with the essential knowledge to protect your employees and ensure regulatory compliance.

Experience-Based

Training

- Industry Expertise: Trainers with decades of real-world experience and deep knowledge of industry standards.

- Certified Instructors: Experienced experts in safety and hazardous energy control.

- Professional Development: Earn PDH while enhancing workplace safety.

Customizable & Comprehensive Content

- Training material can be customized to suit different roles, experience levels, and industries

- Versatile and applicable to a wide range of professionals

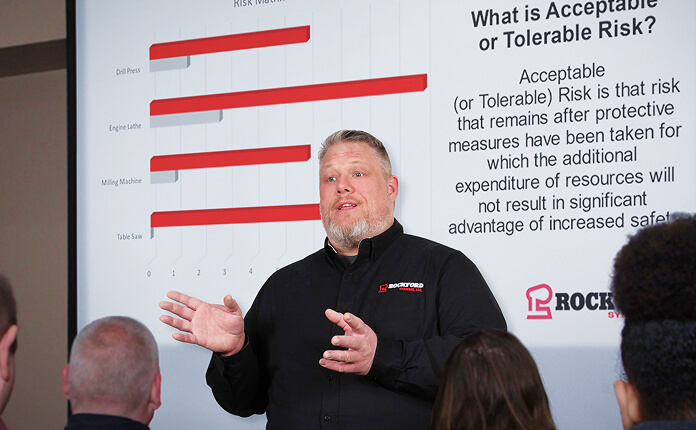

Interactive Learning with leading experts

- Highly interactive training format

- Utilizes various props and hands-on techniques

- Ensures practical understanding of safety concepts

- Focuses on real-world application and skill-building

WHY TRAIN WITH ROCKFORD SYSTEMS?

For over 50 years, Rockford Systems has been dedicated to educating organizations on workplace safety solutions, risk aversion, and regulatory compliance. We provide comprehensive training and safety solutions across various industries, helping businesses mitigate hazards and meet industry standards such as NFPA compliance. Our training programs cover essential topics, including machine safeguarding, lockout/tagout (LOTO), compliance, and loss control, combustion safety ensuring that safety managers, engineers, and other personnel responsible for workplace safety have the knowledge they need to protect employees and maintain regulatory compliance. Additionally, our combustion safety solutions address fuel-train management and operational risks, reducing hidden hazards and preventing equipment downtime.

Training Seminar and Workshop Offerings

This 2-day workshop provides comprehensive knowledge of combustion safety, including hands-on simulations, covering equipment fundamentals, practical application, troubleshooting, standards, and hazard awareness, with a Certification of Completion awarded at the end.

Rockford Systems offers a 2-day Machine Safeguarding Seminar and an interactive online training program, featuring daily bite-sized classes and hands-on demonstrations, providing advanced machine safeguarding knowledge over the course of a week.

Join our three-day, in-person seminar to master machine safeguarding, workplace safety compliance, and Lockout/Tagout (LOTO) procedures, covering OSHA, ANSI B11, and NFPA 79 standards with hands-on training for a safer, compliant workplace.

The Authorized Lockout/Tagout Training equips participants with the knowledge and skills to safely implement procedures in compliance with OSHA 29 CFR 1910.147, minimizing the risk of workplace accidents by effectively controlling hazardous energy during maintenance and servicing activities.

Join us for an engaging workshop on Lockout/Tagout (LOTO), where participants will learn to control hazardous energy during maintenance, servicing, and repairs, ensuring a safer work environment through expert guidance and practical insights.

This immersive 2-day seminar equips safety consultants, inspectors, and Insurance Loss Control professionals with the tools to interpret OSHA regulations, identify hazardous exposures, and utilize consensus standards like ANSI, ISO, NFPA, and NIOSH to ensure safety and compliance.

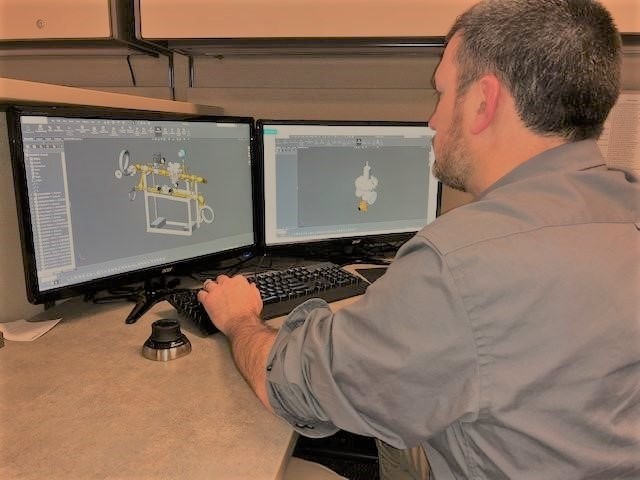

Fully Equipped Training Center

The Rockford Systems Training Center is equipped with several types of risk reduction so that attendees can see how different safeguards can be applied and used.

All training courses are held at our Rockford, Illinois, training center, which is located 70 miles northwest of Chicago O’Hare Airport.

Rockford Area Hotel Accommodations

Check out our hotels offering at preferred rate when booking for Rockford Systems training programs.

Our Expert Trainers

Meet our trainers, whose decades of real-world experience ensure that training materials are tailored to your safety needs, providing expertise for optimal results.

Let’s Talk Training Have additional questions about our training offerings?

Contact us today for more information on how Rockford Systems training offerings can help in your workplace.