Emergency Stop Safety Relay – Single Channel (RFT148)

$761.77

Product Description

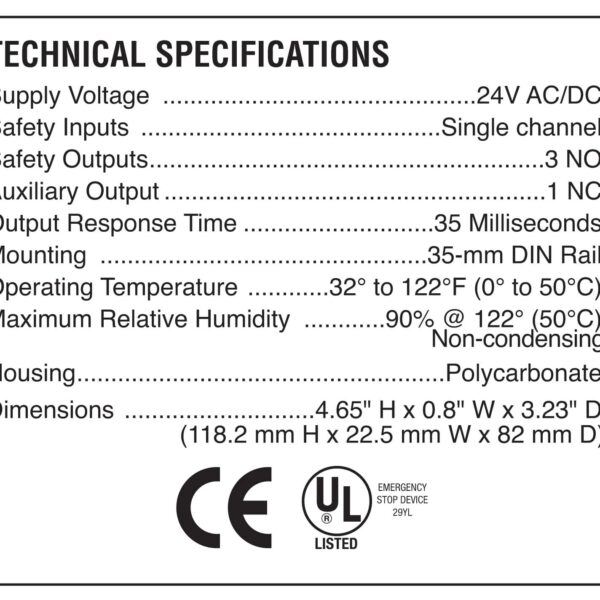

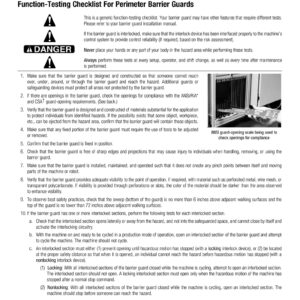

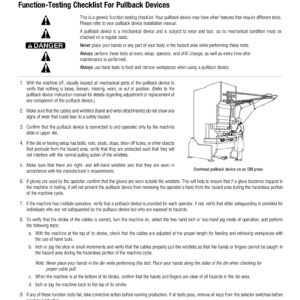

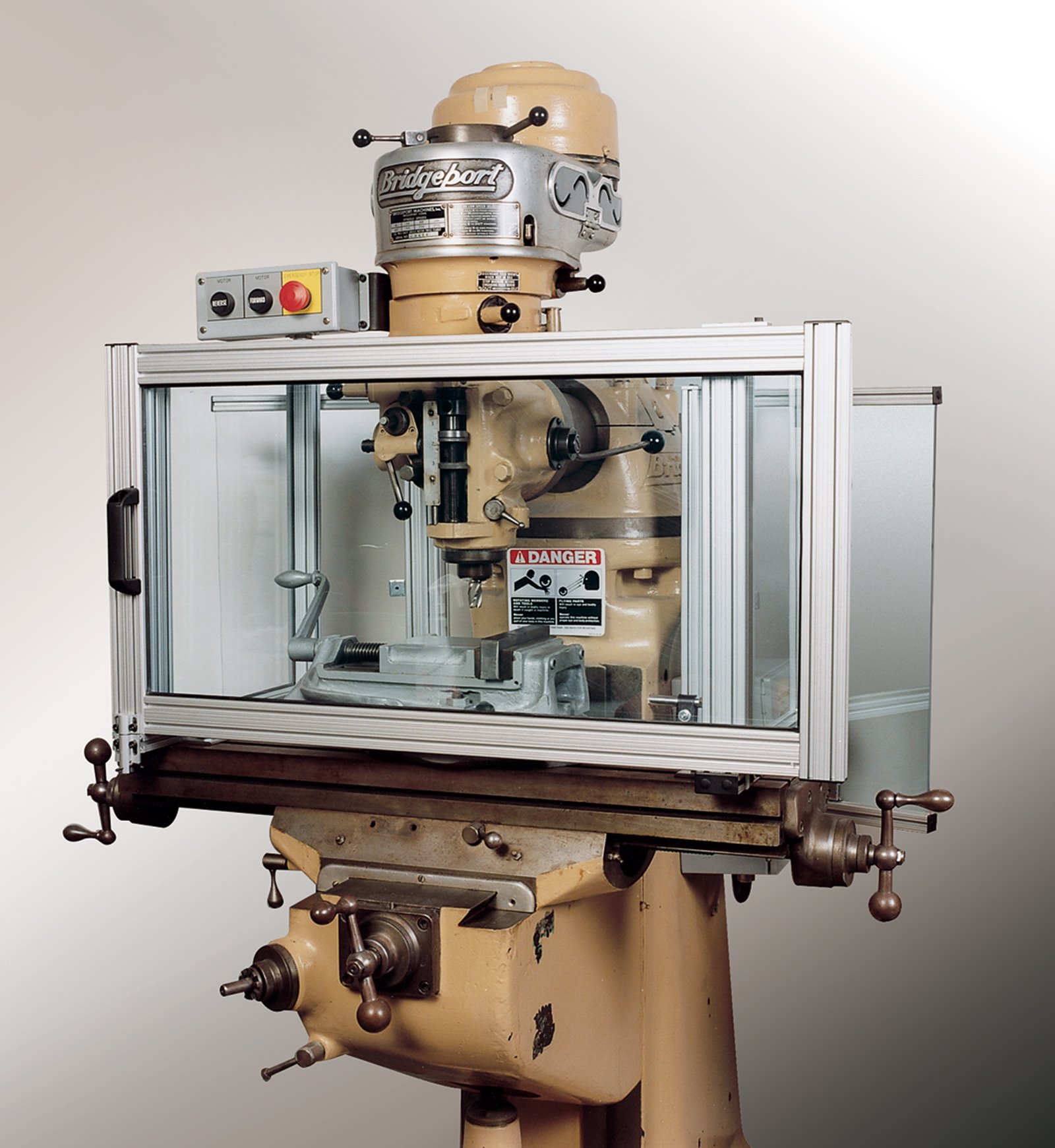

An Emergency Stop Safety Module is used to increase the control reliability of an emergency stop circuit. The Single-Channel Emergency Stop Safety Relay monitors one single-channel normally closed Emergency Stop switch circuit for a contact failure or wiring fault. When using a single channel emergency stop safety relay, the wiring is monitored and compared. If a failure occurs in one area, it will be detected and a stop signal will be sent to the safeguarded machine or hard guards, to protect personnel from hazardous machinery.

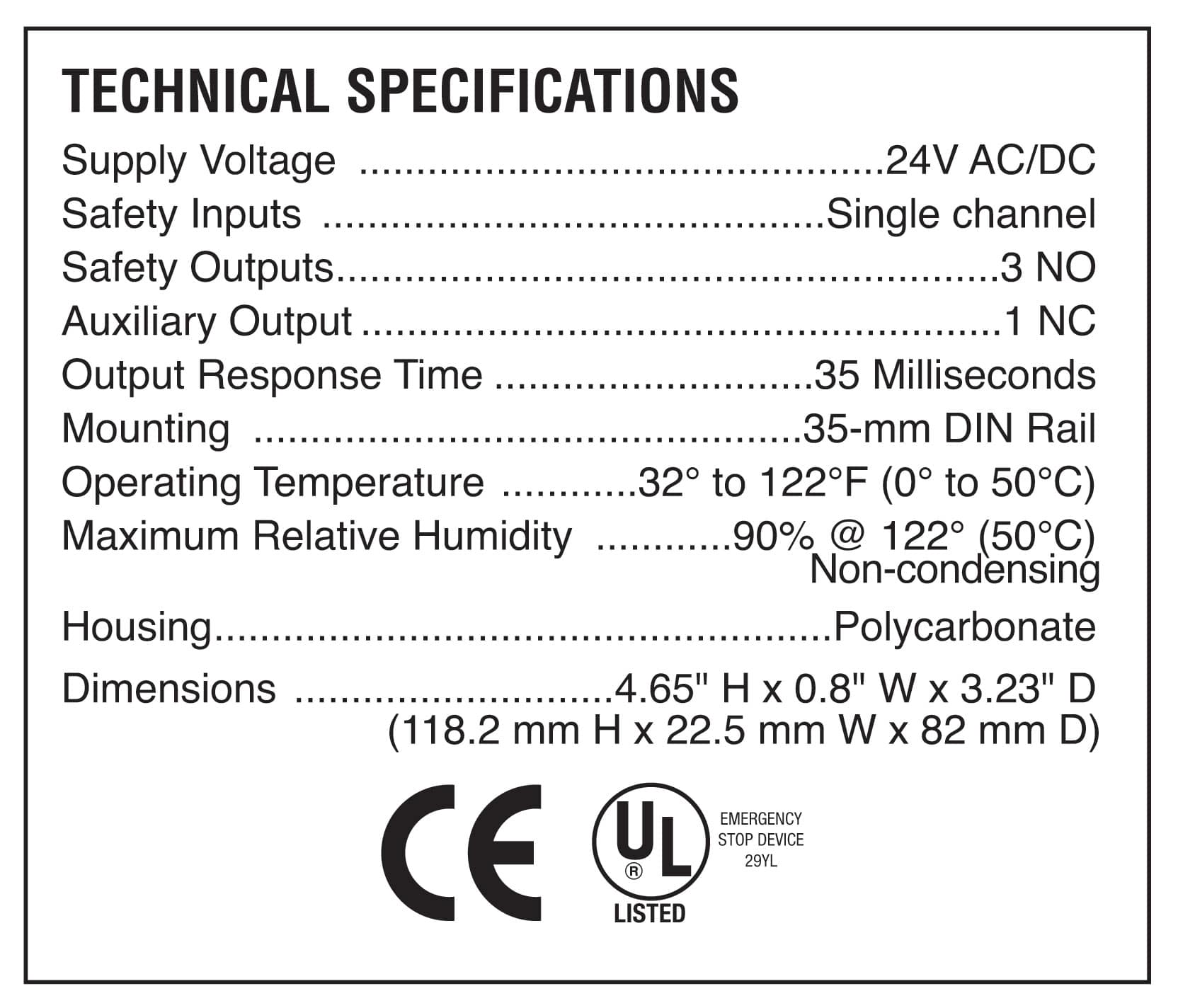

- Three output switching channels for connection to control-reliable power interrupt circuits

- Auto reset or manual reset

- One auxiliary non-safety N/C output contact for status monitoring by process controller

- Design complies with standards UL991, EN418, and EN954-1 (Safety Category 2)

- For use in functional stop category 0 applications per NFPA 79 and EN418

- 6 amp safety output contacts

A Single-Channel Emergency Stop Safety Relay is designed to connect safety devices, such as interlock switches, to the machine control circuit. It provides a switching action from the safety interlock switch, and can act as an intermediate relay to distribute a signal to multiple devices. The relay compares input and output signals, and provides failure to a safe condition if there is a failure in the interlocking interface control circuit.

The purpose of an Emergency Stop Safety Module (E-Stop Safety Module) is to increase the control reliability of an emergency stop circuit. The ANSI B11.19 standard states:

“Control reliability of electrical, electronic, or pneumatic systems frequently consists of multiple, independent parallel or series circuitry or components so arranged that any single failure … either sends a stop command to the machine tool or prevents a successive cycle from being initiated.”

- Interlocked guards, light curtains, laser scanners, safety mats

- Machine input/output signals

WARNING: Not a Stand-Alone Safeguarding Device

This device is not a stand-alone point-of-operation guarding device, as defined by OSHA regulations. It is necessary to install point-of-operation guarding devices, such as safety light screens and/or hard guards, to protect personnel from hazardous machinery. Failure to install point-of-operation guards on hazardous machinery can result in a dangerous condition which could lead to serious injury or death.

Contact Customer Service

Reach a Real Person @: 1-800-922-7533

Open Monday – Friday, 8:00am – 5:00pm CST

Same Day Support Response