Detect-A-Finger Gen II Drop-Probe Device For Riveters (RKC008/RKC009)

$1,899.56

Product Description

Enhanced Safety with Rockford System’s Detect-A-Finger Gen II Drop-Probe Device

In industries that rely on riveters and welders, ensuring the safety of operators is paramount. Rockford System’s latest innovation, the Detect-A-Finger Gen II drop-probe device, takes safety to a new level by providing enhanced features.

Key Features of Detect-A-Finger Gen II:

- Extended Stroke: The Gen II boasts a longer stroke, reaching up to 1.85 inches. This improvement allows for better protection of the operator’s fingers from pinch-point hazards, reducing the risk of injuries.

- Unified Right- and Left-Handed Operation: The device is designed for both right- and left-handed operation, offering flexibility and ease of use for operators regardless of their dominant hand. This enhancement contributes to a more user-friendly and efficient experience.

- Pre-Punched Enclosure: Faster electrical connections are achieved with the Gen II’s pre-punched enclosure. This design streamlines the installation process, making it quicker and more convenient for operators and maintenance personnel.

- Softer Probe Rod: The softer probe rod ensures accurate template development, adding an extra layer of safety. This feature not only enhances precision but also contributes to a more comfortable and reliable operation.

- Operator Bypass Reduction: The Gen II is engineered to minimize the potential for operator bypassing, providing an added layer of security. This proactive approach reduces the likelihood of accidents and enhances overall workplace safety.

Versatile Applications:

Detect-A-Finger Gen II drop-probe devices find application in various small machines, including riveters, eye letters, stakers, staplers, crimpers, and fastening machines. Their purpose is to safeguard operators from point-of-operation hazards, creating a secure working environment.

Easy Retrofitting:

One of the standout features of the Gen II is its identical mounting pattern to the original model. This “drop-in” solution ensures a quick and straightforward retrofitting process for older models. Organizations can easily upgrade their existing systems without extensive downtime or complex installation procedures.

In conclusion, Rockford System’s Detect-A-Finger Gen II drop-probe device represents a significant advancement in workplace safety for industries utilizing riveters and welders. With its enhanced features, compliance with Category 2 safeguarding, and user-friendly design, the Gen II provides a safer and more cost-effective solution, contributing to a secure and efficient work environment.

NOTE: EXTENDED LEAD TIMES APPLY (2 WEEKS)

For organizations that use riveters and welders, the new and improved Detect-A-Finger Gen II drop-probe device helps to protect the operator’s fingers from pinch-point hazards and meets the compliance requirements for a Category 2 safeguarding device. The Gen II upgrades include a longer stroke up to 1.85?, unified right- and left-handed operation, a pre-punched enclosure to achieve faster electrical connections, and a softer probe rod for accurate template development, designed to provide a safer and more cost-effective solution that reduces the potential for operator bypassing. The Detect-A-Finger® drop-probe devices are used on small machines, such as riveters, eye letters, stakers, staplers, crimpers, and fastening machines, to help protect the operator’s fingers from point-of-operation hazards. To make retrofitting older models quick and easy, the Gen II features the identical mounting pattern as the original model, creating a “drop-in” solution that is simple to deploy.

How It Works

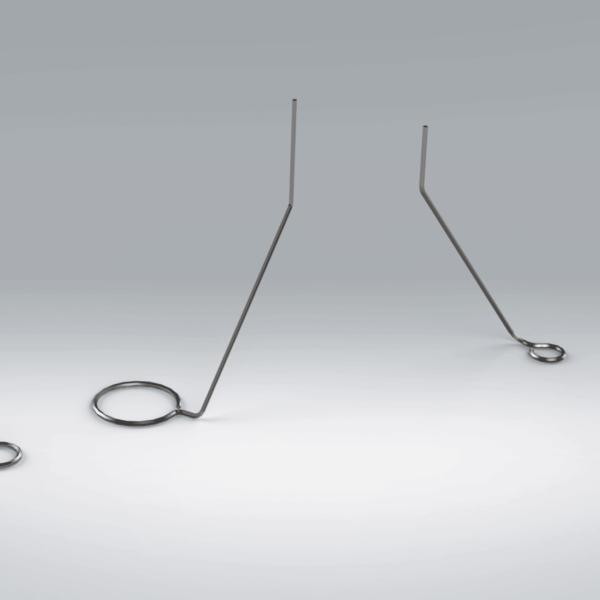

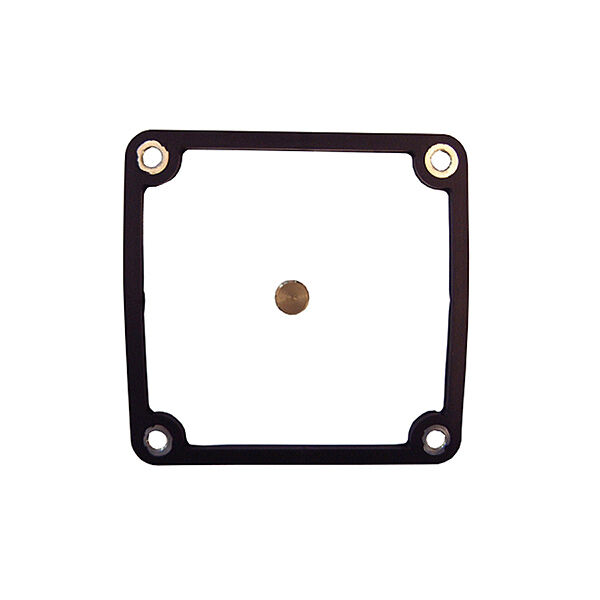

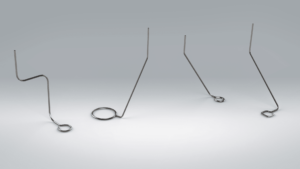

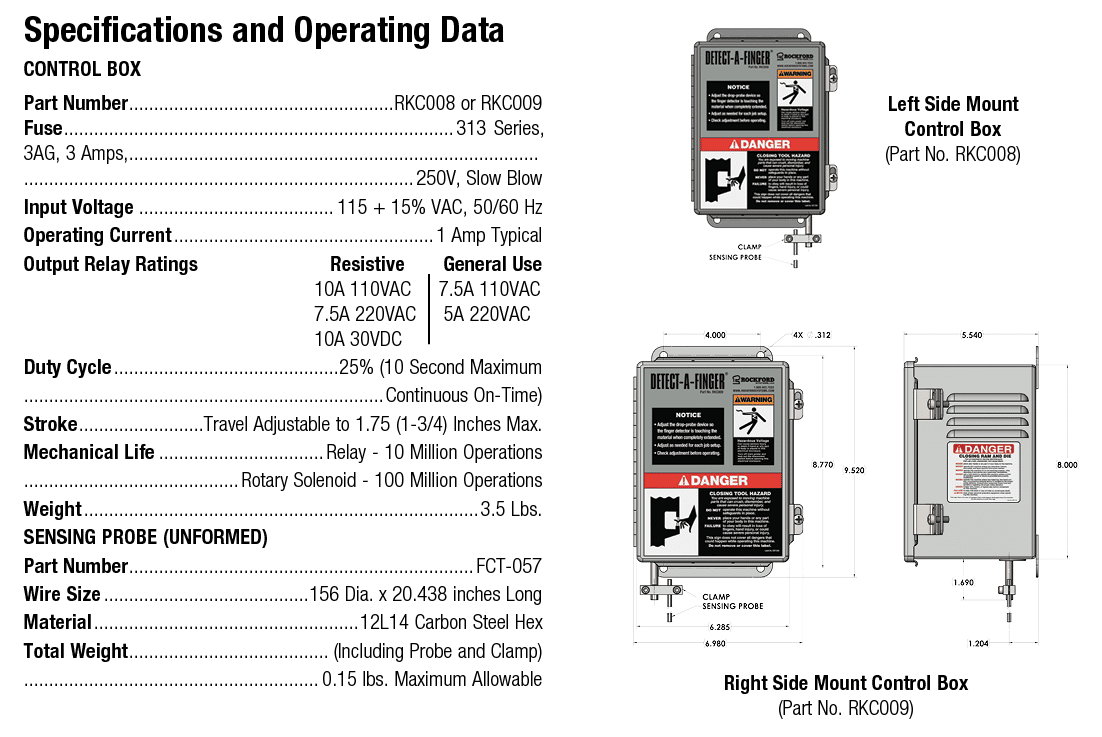

The aluminum “template” probe is shaped by the user to fit each application. This template is then used as an aid to facilitate the forming of the “permanent” steel hexagonal drop probe, which can be adjusted from 0″ to 1.85″ and keyed to the device, thereby preventing operator bypassing. These devices are designed to drop by gravity. If a finger or workpiece is in the way of the probe and the probe is not allowed to complete its downward travel, the machine will not start a cycle or stroke. On these models, the rotary solenoid is in the control box and when energized, after initiation of the cycle, allows the probe to drop. A spring returns the probe to its starting or up position. Another drop-probe device uses interlocking cams in its operating mechanism. The control box consists of the probe arm, rotary electric solenoid, two-hand control safety relay, redundant limit switches, basic circuit with terminals and other mechanical mechanisms. On machines that are mechanically operated, an air cylinder or electric solenoid may have to be added to the operating linkage to trip the machine. On machines that are hydraulically or pneumatically operated, the drop-probe control can usually be interfaced with the existing control system.

When updating machines to meet safety standards, please make sure that each machine is looked at as an individual system that includes, but is not limited to, safeguarding (drop-probe device), machine control, disconnect switch, motor starter, covers for rotating components, auxiliary parts, lockout/tagout equipment, and feeding and retrieving of workpieces. Two 20? drop-probe rods are furnished with each control box: one aluminum template and one hexagonal steel permanent rod. These rods are shaped by the user for the workpiece or assembly requirements.

Sequence of Operation

The operator initiates the cycle of the machine usually by an overt action on the foot switch. This energizes the rotary solenoid in the control box, which allows the drop probe to drop until it makes contact with a limit switch. If an obstruction, such as a finger, gets in the way of the probe, the limit switch is not contacted and the machine does not start its cycle. If nothing obstructs the probe and the limit switch is operated, a relay will signal the machine to start its cycle or cause it to trip. Next, the relay drops out, de-energizing the control box solenoid, allowing the probe to move up and out of the way. At this time, the machine completes its cycle and stops. The foot switch must be released and re-initiated to begin another cycle.

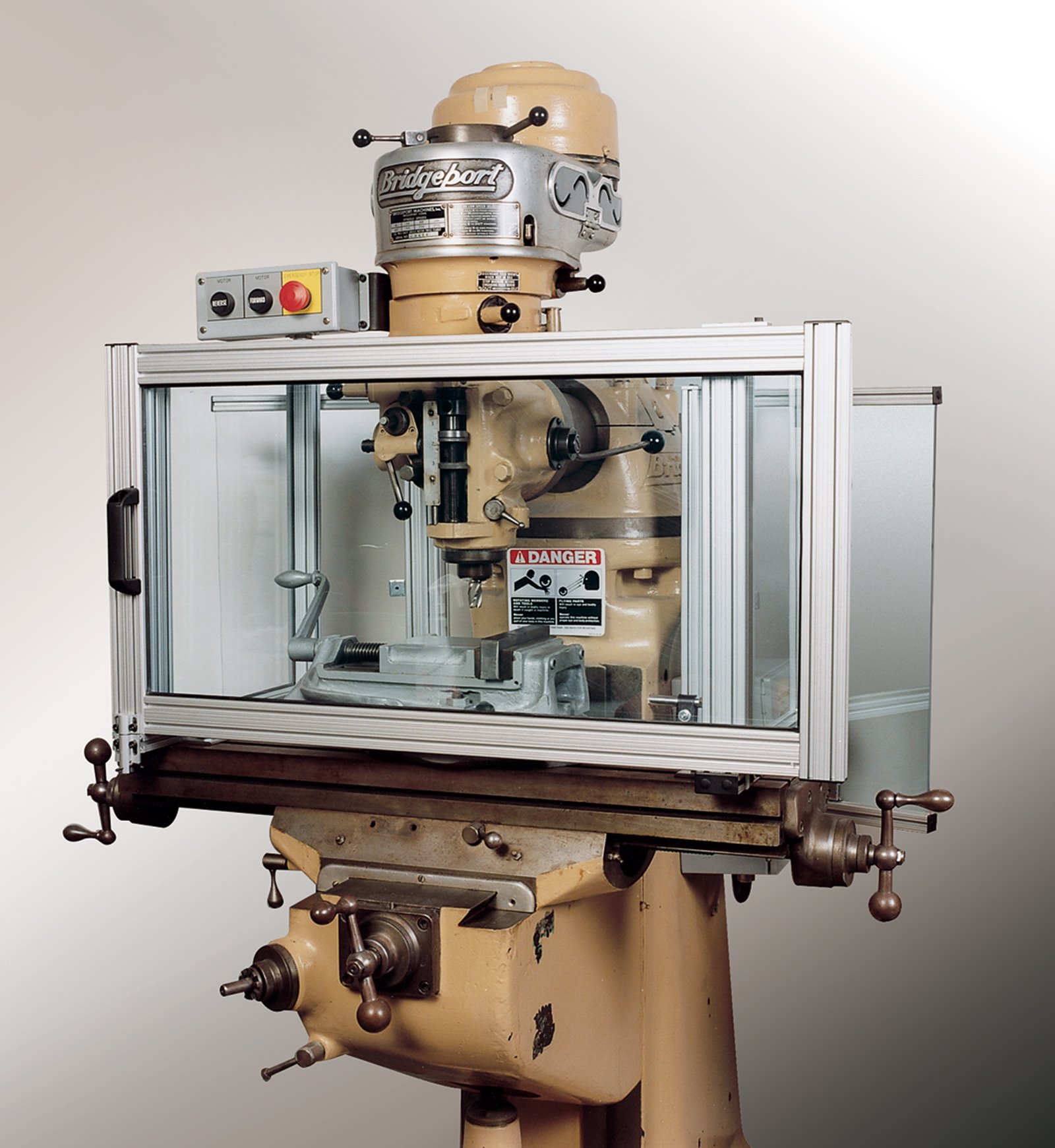

The Detect-A-Finger Gen II is available in two models: Part No. RKC009 is for mounting on the right side of a machine (probe on left), and Part No. RKC008 is for mounting on the left side of a machine (probe on right). Rockford Systems also offers a new drop-probe kit (FCT057), that includes a clamp, one soft aluminum rod to aid in creating a template, and one tougher steel hex probe. If needed, add the FOOT SWITCH (CTD088). Complete installation instructions and a maintenance manual are furnished with each device.

Select the Detect-A-Finger® Gen II For Riveters that allows the sensing probe to enter the point of operation, without obstructing the work area, and provides for as short and rigid of a sensing probe design as possible.

Alternative Pinch-Point Safety System

Our new, premium solution – the UNITROL SOFT TOUCH Pinch-Point Safety System – is the first and only fully passive safeguarding equipment designed to prevent a pneumatic riveter, welder or other small machine from applying full force if it detects fingers in the machine’s point-of-operation area by measuring electrical continuity between electrodes. If anything other than metal is present between the electrodes, their sensors will not detect continuity and the electrodes will open automatically.

Click HERE for more information on the UNITROL Soft Touch for Riveters and HERE for UNITROL Soft Touch for Welders.

Please call 1-800-922-7533 to learn more about Rockford Systems’ range of riveting and welding safety solutions.

Contact Customer Service

Reach a Real Person @: 1-800-922-7533

Open Monday – Friday, 8:00am – 5:00pm CST

Same Day Support Response