Products \ Machine Safeguarding \ Presence Sensing Devices \ Light Curtains

-

$1,318.33 – $9,647.46Select options This product has multiple variants. The options may be chosen on the product page

-

$508.38 – $1,320.17Select options This product has multiple variants. The options may be chosen on the product page

-

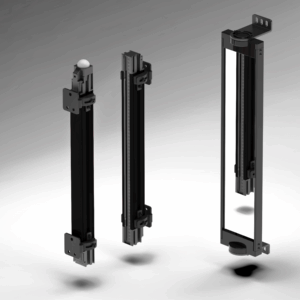

$868.28 – $3,360.15Select options This product has multiple variants. The options may be chosen on the product page

-

$658.48 – $2,333.71Select options This product has multiple variants. The options may be chosen on the product page

-

$59.73Select options This product has multiple variants. The options may be chosen on the product page