Control Hazardous Energy With Lockout Tagout Software

Built for speed, convenience, and compliance. Operating an OSHA 1910.147 compliant lockout tagout program has never been easier. Traditional methods of creating lockout tagout procedures can take hours of back-and-forth, highly inefficient work on multiple devices.

Smart Safety Pro Lockout Tagout software takes the hassle out of building LOTO procedures with a powerful, intuitive mobile app. Simply snap a picture of each energy source, annotate, then add lockout, verification, and return to service steps. Digitally audit the procedure, print, and done!

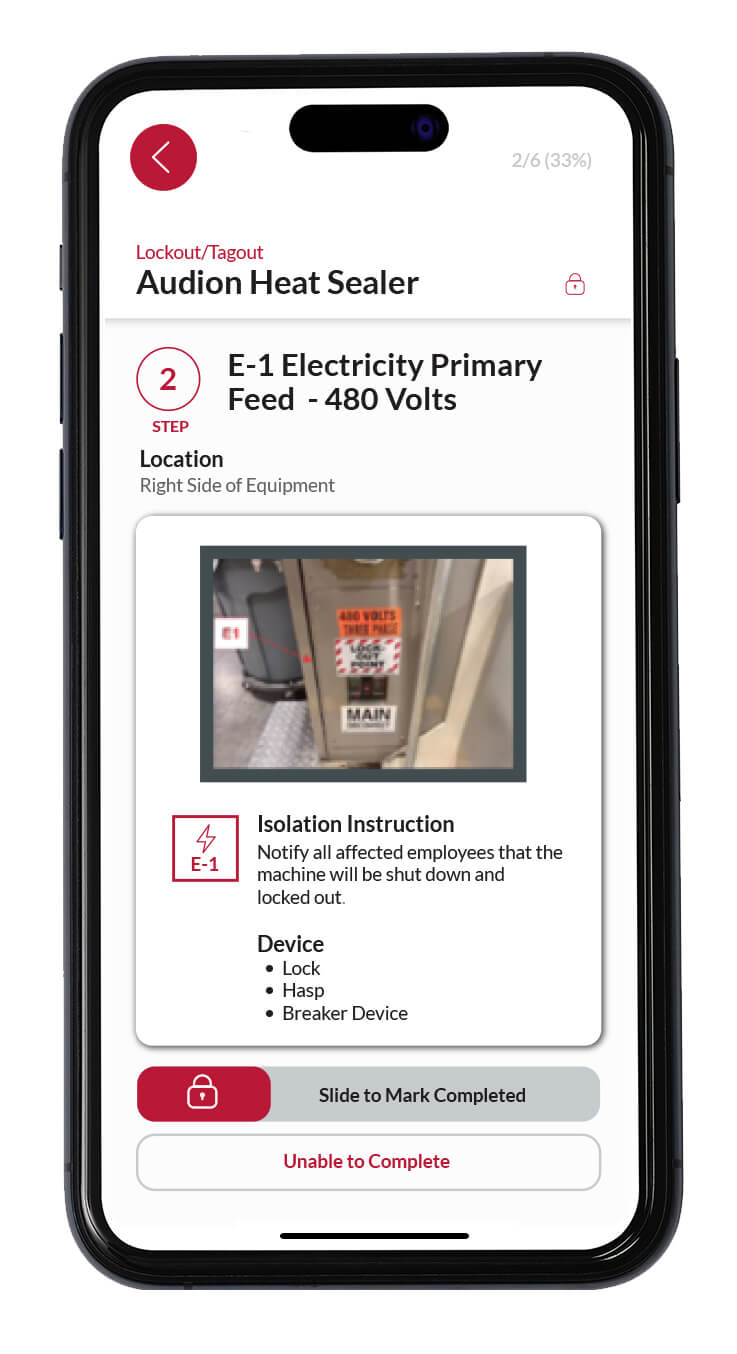

Each lockout tagout procedure report includes a QR code that can be scanned on-demand when equipment needs to be locked out. Isolation instructions, verification steps, and images are displayed step-by-step, and the technician verifies that each step is completed.

Lockout Tagout Software Features

Build a Lockout Tagout Procedure 90% Faster

Procedure Builder

Report Formatting

Lockout Execution

Lockout Tagout Validation

WiFi Not Required

Disconnected App

Audit Management

Automatic Scheduling

Training Management

Training Permissions

Audit Trail

Digital Lockout Verification

Mobile LOTO Procedure Builder

Equipment Fielding

Start by uploading the facility’s equipment list into the lockout tagout software, or use our handy field setup module to scan equipment into the system.

Procedure Creation

The lockout tagout software begins with a photo of an energy source. Add tags and arrows right from the photo screen. Quickly select a predefined energy type, feed, magnitude, location, isolation, devices, and verify method. Repeat for each energy source until the procedure is complete.

Procedure Approval

After LOTO procedure is finished and submitted it is ready for approval. The Authorized User can review the procedure in the mobile app, make any necessary changes, then digitally approve it. This activates the procedure QR code so that it can be scanned to auto-launch the mobile procedure execution anytime lockout tagout is required.

On Demand Mobile Lockout Tagout

The lockout tagout software mobile app has an express access workflow for employees who only need to perform equipment lockout or return to service functions. A simple scan screen directs the employee to scan the QR code on the procedure. This scan auto-launches the digital procedure and walks the employee through each lockout and verification step. The employee verifies that each step was completed before moving on to the next one. In the instance that the employee cannot scan the equipment or procedure QR code, the employee can browse the equipment list and search for the equipment. The site map can also be launched to navigate through the facility setup into a particular building, floor, and zone for a view of equipment in that area.

Equipment Insights

When employees need to do more than an on-demand equipment lockout or return to service, the equipment status screen offers full visibility into the equipment and access to a multitude of task options. Things that can be done from this screen include:

- View equipment operation status & most recent lockout event

- View procedure status and next audit due date

- View open issues and/or create a new issue

- View and complete issue corrective actions

- Launch and complete equipment lockout

- Launch and complete equipment minor servicing

- Launch and complete procedure audit

- Launch and document employee training audit

- View equipment details including serial, manufacturer, model, and energy sources

Lockout Tagout Consulting Services

Need Help Getting Started?

Although Smart Safety Pro Lockout Tagout software is very simple to use, many organizations need help getting started or identifying gaps in their current safety system, addressing them, and implementing a compliant lockout tagout system. Smart Safety Pro has partnered with industry leading consultants at Rockford Systems to offer varying levels of implementation, depending on the needs of the company. Service offerings include program gap analysis, machine specific procedure creation, program development, train-the-trainer, and OSHA 1910.147 compliant authorized training. Rockford Systems consultants are Smart Safety Pro lockout tagout software experts, and offer their services simultaneously along with lockout tagout software implementation and training.

Service Offerings

Our approach goes beyond surface-level evaluations, delving deep into your company policies, program elements, and workforce knowledge of the LOTO program.

Using our proprietary RSLOTO Software, we conduct thorough assessments of each machine, identifying energy sources, potential hazards, and isolation points.

Our specialized team is dedicated to crafting tailored LOTO programs designed to meet your specific needs while ensuring compliance with OSHA 1910.147.

Our concise and comprehensive training equips employees with the knowledge and skills to safely implement LOTO procedures, minimizing workplace hazards.

Our expert instruction covers standards, regulations, and best practices in workplace safety. Through engaging activities, participants develop the skills to implement LOTO protocols effectively.

Lockout Tagout Software Blog

Get In Touch With Us

"*" indicates required fields