Category: Power Presses

Showing 25–48 of 108 results

-

Stop-Time Measurement (STM) Device Complete (DCL100)

$15,603.68Complete STM including meter, transducer, cable extension set, actuator, flag, legs, and plunger extension. This is a non-stock item and may incur an extended delivery time.

-

Remote Tachometer Assembly (DCL101)

$3,097.46Optional remote tachometer assembly (for reciprocating machines that stop beyond bottom or top, and for machines with relatively slow rotating or linear motion). For STM (Stop-Time Measurement) Device

-

N.O. Manual Start Switch (DCL102)

$415.90The N.O. Manual Start Switch is designed to be compatible with a large variety of practical machinery application needs.

-

Die Safety Block Holders

$195.53 – $459.34These die safety block holders are designed to accept U-shaped, octagonal, X-shaped, and adjustable safety blocks. They are constructed of heavy-gauge steel and painted safety orange. The holders attach easily to the machine with two 1/4-inch fasteners. A strap is furnished with each holder to keep the block in place. Safety wedges can also be…

-

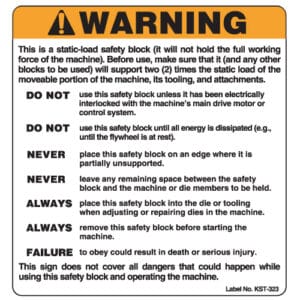

Warning Labels for Die Safety Blocks (KST323-KST323S)

$20.57The Die Safety Block Warning Labels (KST323-KST323S) These visual safety tools are designed as visual safety tools to raise awareness of the dangers of die safety blocks nearby. These signs are available in English and Spanish.

-

Die Safety Block Wedges

$178.47 – $1,101.80.embed-container { position: relative; padding-bottom:56.25%; height:0; overflow: hidden; max-width: 100%; } .embed-container iframe, .embed-container object, .embed-container embed { position: absolute; top: 0; left: 0; width: 100%; height: 100%;}

-

Double-Cup Sheet Metal Lifters

$197.07 – $226.56Convenient Handled, Double-Cup Sheet Metal Lifters These lifters have a convenient handle for one- or two-handed lifting. Positive grip increases the operator’s working capacity. Dual trigger valves disengage the lifter from material. The 3″ cups lift about 30 pounds; the 4″ cups about 50 pounds; and the 5″ cups about 75 pounds.

-

Double-Cup Verti-Lift

$690.56 – $699.88Double-Cup Verti-Lift with Powerful Suction Capabilities Powerful suction cups are used to lift and move loads from the floor without having to bend over. It has a handy trigger-valve release to disengage the vacuum lifter instantly and safely. These hand-operated vacuum lifters are used for repeated lifting and moving of non-porous materials on the ground…

-

Dual-Solenoid Air Valves for Full-Revolution Presses (RCD140)

$2,864.68This 1/4″ monitored dual-solenoid air valve is ideal for operating air cylinders on full-revolution presses. It is equipped with a pressure switch with both normally open (NO) and normally closed (NC) contacts to provide feedback to the control system indicating whether the valve is in the ready-to-run condition or has experienced an abnormal function. This…

-

Dual-Solenoid Air Valves for Mechanical Power Presses and Press Brakes

$2,397.57 – $9,085.98These monitored dual solenoid air valves are ideal to use on mechanical power presses and other potentially hazardous machinery that utilize a pneumatically controlled clutch and brake mechanism. Each valve has two valve elements independently controlled by two solenoid pilots. The two valve elements share common inlet, outlet, and exhaust ports. When the pilot valves…

-

-

Emergency Stop Safety Relay – Single Channel (RFT148)

$732.47An Emergency Stop Safety Module is used to increase the control reliability of an emergency stop circuit. The Single-Channel Emergency Stop Safety Relay monitors one single-channel normally closed Emergency Stop switch circuit for a contact failure or wiring fault. When using a single channel emergency stop safety relay, the wiring is monitored and compared. If…

-

Emergency Stop Safety Relay – Dual Channel (RFT149)

$1,215.09An Emergency Stop Safety Module is used to increase the control reliability of an emergency stop circuit. The Dual-Channel Emergency Stop Safety Relay monitors emergency stop devices, such as palm buttons and rope/cable pulls, and positive-opening safety switches used for guard/gate interlocking. It is designed to connect safety devices, such as interlock switches, to the…

-

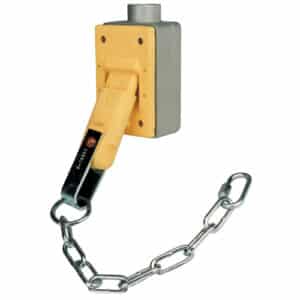

Die Safety Block Electrical Interlock

$538.49 – $1,112.66According to ANSI B11.19-2003, safety blocks “shall be interlocked with the machine to prevent actuation of hazardous motion of the machine.” The following interlock systems will satisfy this requirement. The electrical interlock system for die safety blocks must be interfaced into the control system so that when the plug is pulled, the power to the…

-

Enclosed Transformers

$578.84 – $712.29Direct Frame-Mounting Station, Enclosed Transformers These transformers comply with OSHA regulations and ANSI standards and are available for use when the motor start/stop station is remotely located from the starter enclosure, and voltage to these buttons must be 115 V or less. These transformers mount directly to the frame of the machine. If the existing…

-

Energy Source ID Tags

$4.82 – $13.19Energy Source Attachment ID Tags for Hazard Awareness These tags can be used to identify the different hazardous energy sources associated with machinery throughout a plant or factory. They can be permanently or temporarily attached at the energy source. These tags can be used in conjunction with a company’s energy control program. All tags are…

-

-

Filter-Regulator-Lubricators (FRLs)

$519.86 – $2,726.56 -

Flywheel Rotation Sign

$19.78Flywheel Rotation Sign for Visual Danger Attention The Flywheel Rotation Sign for Visual Danger Attention are danger signs for flywheel rotation. Includes arrow pointing to flywheel danger.

-

Foot Switch Yellow (CTD011)

$1,319.05Keeps operators hands free from machinery by using die-cast foot switches, designed for use on machinery with proper “Point of Operation” and “Pinch Point” guarding devices in place. This foot switch is protected from unintentional operation. A die-cast cover protects the top and both sides, and the front is protected by a hinged flap. The…

-

Foot Switch Signs (KSC055-KSC055S-KSC055F)

$35.70The Foot Switch Signs and Labels are designed for visual awareness and are available in English, Spanish and French.

-

Function-Testing Checklist for Light Curtains (LLL055)

$18.23Light curtains should be function-tested often using the function-testing checklist at every setup, operator change, and shift change, as well as every time after maintenance is performed. This light curtain function-testing checklist can be used for this. It is laminated and has a grommet in the corner so it can be kept at the machine….

-

Function-Testing Checklist for Point-of-Operation Barrier Guarding (LLL058)

$18.23Barrier guards should be function-tested at every setup, operator, and shift change, as well as every time after maintenance is performed. This point-of-operation barrier guard function-testing checklist can be used for this. It is laminated and has a grommet in the corner so it can be kept at the machine. The checklist has the function-testing…

-

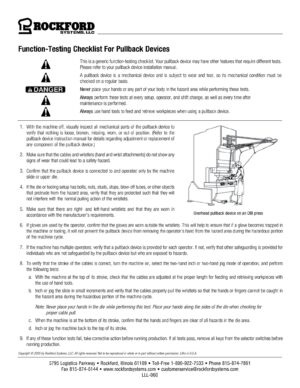

Function-Testing Checklist for Pullback Devices (LLL060)

$18.23Pullback devices should be function-tested at every setup, operator, and shift change, as well as every time after maintenance is performed. This pullback device function-testing checklist can be used for this. It is laminated and has a grommet in the corner so it can be kept at the machine.

Contact Customer Service Reach a Live Person @

Open Monday – Friday

8:00am – 5:00pm CST

Order Online Today

Let Us Help…

Our Mission

To reduce risk and prevent workplace

injuries by becoming our customer’s trusted

advisor and source for machine safeguarding

training, assessment services, and provider

of turnkey engineered safeguarding solutions.

Location

5795 Logistics Parkway

Rockford Illinois 61109

Phone

1-800-922-7533

Useful Links

Hours of Operation

Copyright 2024. All Rights Reserved By Rockford Systems LLC